One-Touch Deceleration & Auto-Idle

One touch deceleration switch on top of LH joystick lowers the engine RPM when selected. The saves fuel by regulating pump and engine. Auto Idle function moderates engine RPM to idle state when machine remains idle for 4 sec by enabling MCU to send a signal to engine. This in turn reduces fuel consumption and operation cost.

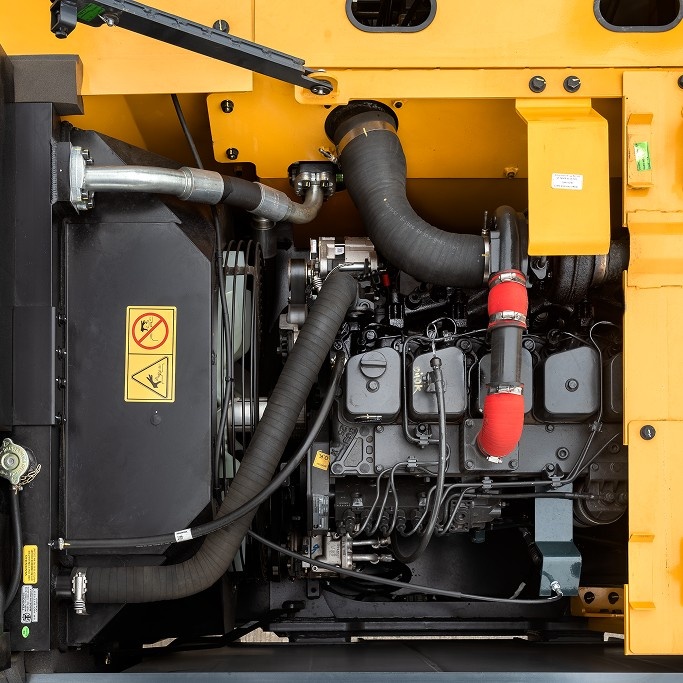

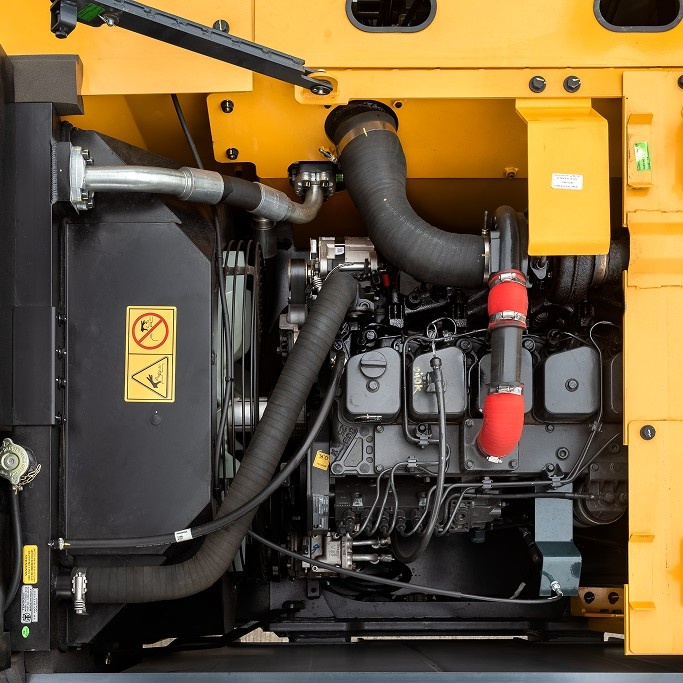

Charge Air Cooler System

The system cools the air as it passes through the turbocharger. It results in cool, high-density air of bigger mass being pumped to the engine. This helps to achieve deliver more power output per unit of fuel burnt and high fuel efficiency.

Comfort

The spacious Air Conditioned cabin creates a very comfortable working environment for the operator. The seat comes with 7 Adjustments including seat height movement. Soft joystick control ensures increased productivity and higher operator efficiency.

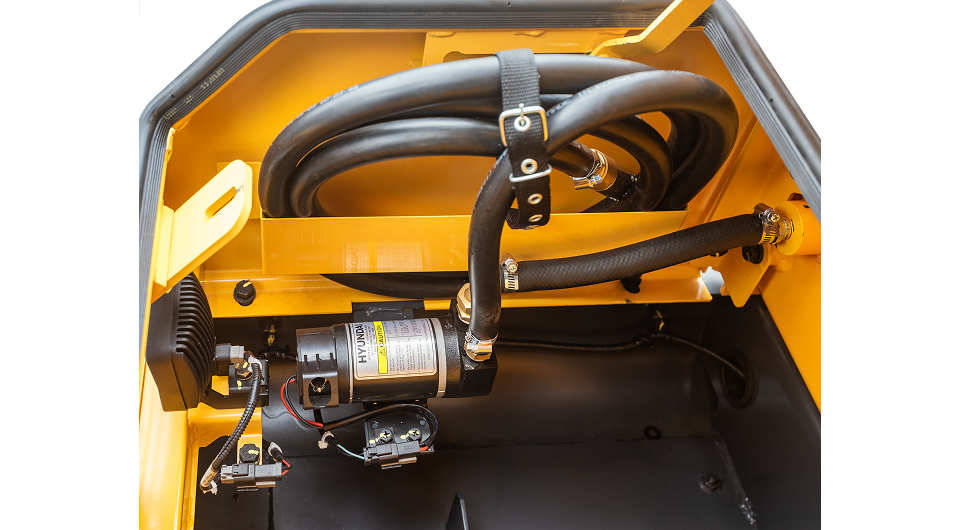

Convenience

The R215L SMART X PLUS Series excavator is equipped with features designed to enhance operational convenience. A removable floor mat for easy cleaning and improved maintenance, helping to keep the operator area neat and well-maintained. The integrated Bluetooth FM radio provides added functionality for communication and entertainment. LED lamps offer improved visibility in low-light conditions, supporting safer and more efficient operations. Additionally, the fuel filler pump simplifies the refueling process, reducing downtime on site.