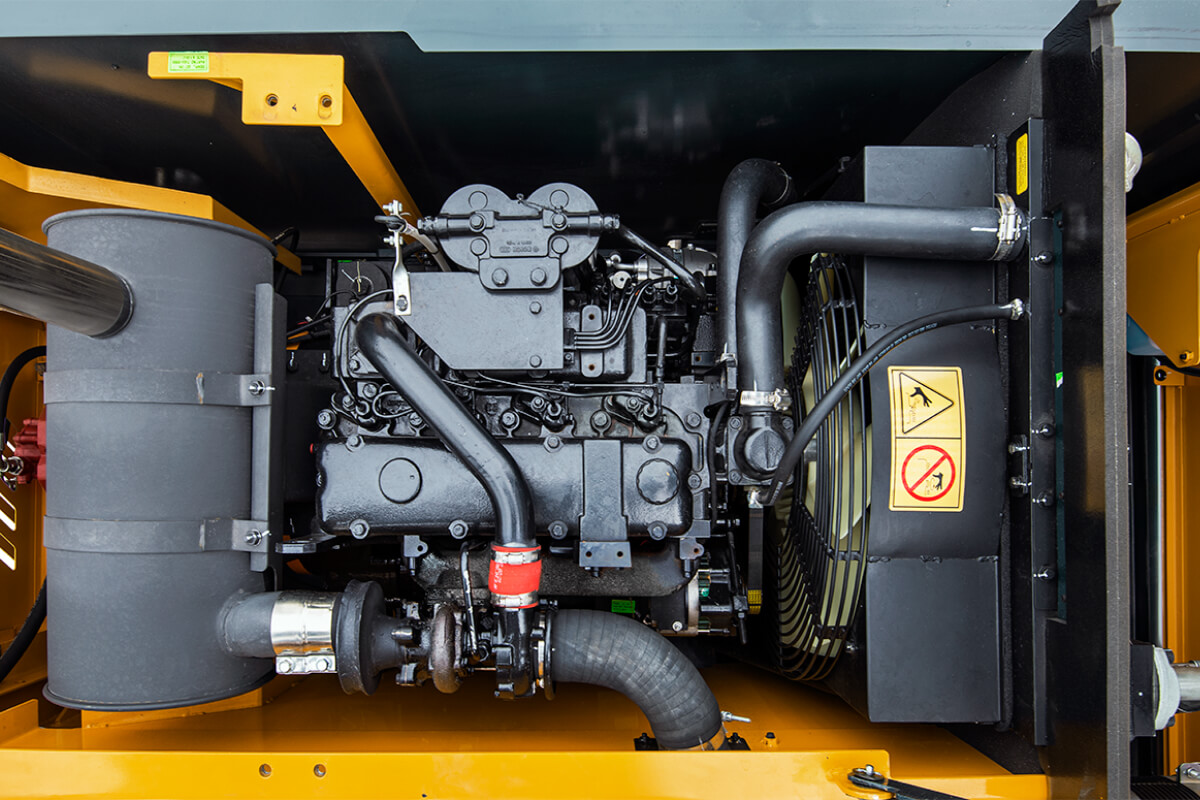

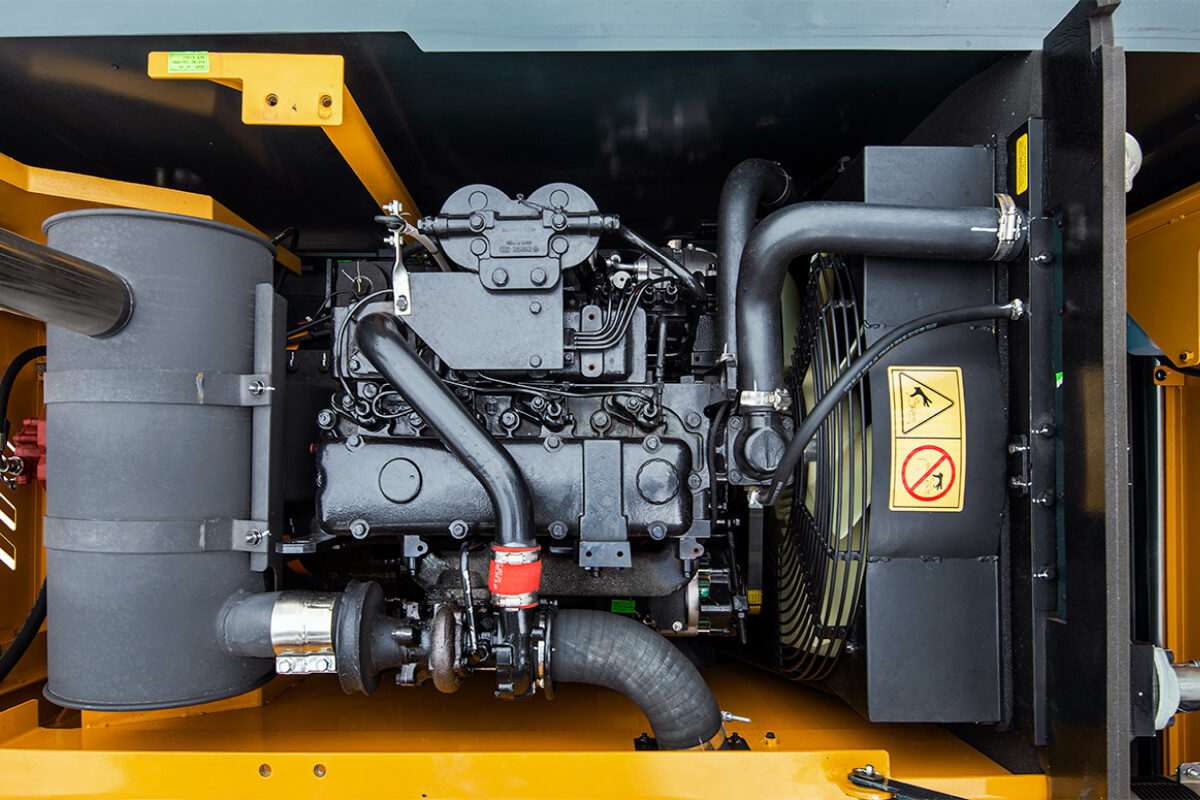

Powerful Engine

The heavy duty, Turbo charged Kirloskar 4R1040T engine develops a gross power of 105 HP @ 2,200 rpm and offers low operating cost, low fuel consumption and extended scheduled maintenance interval of 500 hours.

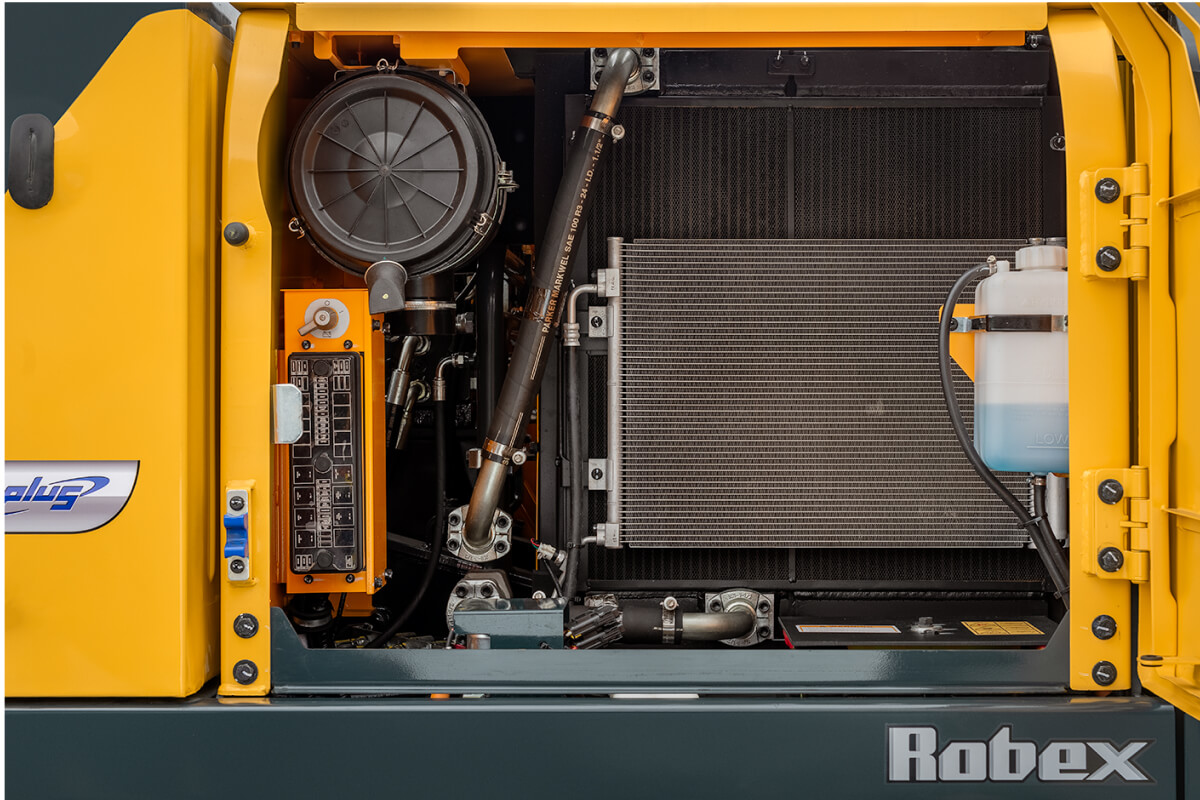

One-Touch & Auto-Idle

One touch deceleration lowers the engine RPM when selected and saves fuel by regulating engine RPM.

Auto Idle function moderates engine RPM to idle state when machine remains idle for 4 sec, which reduces fuel consumption and operation cost.

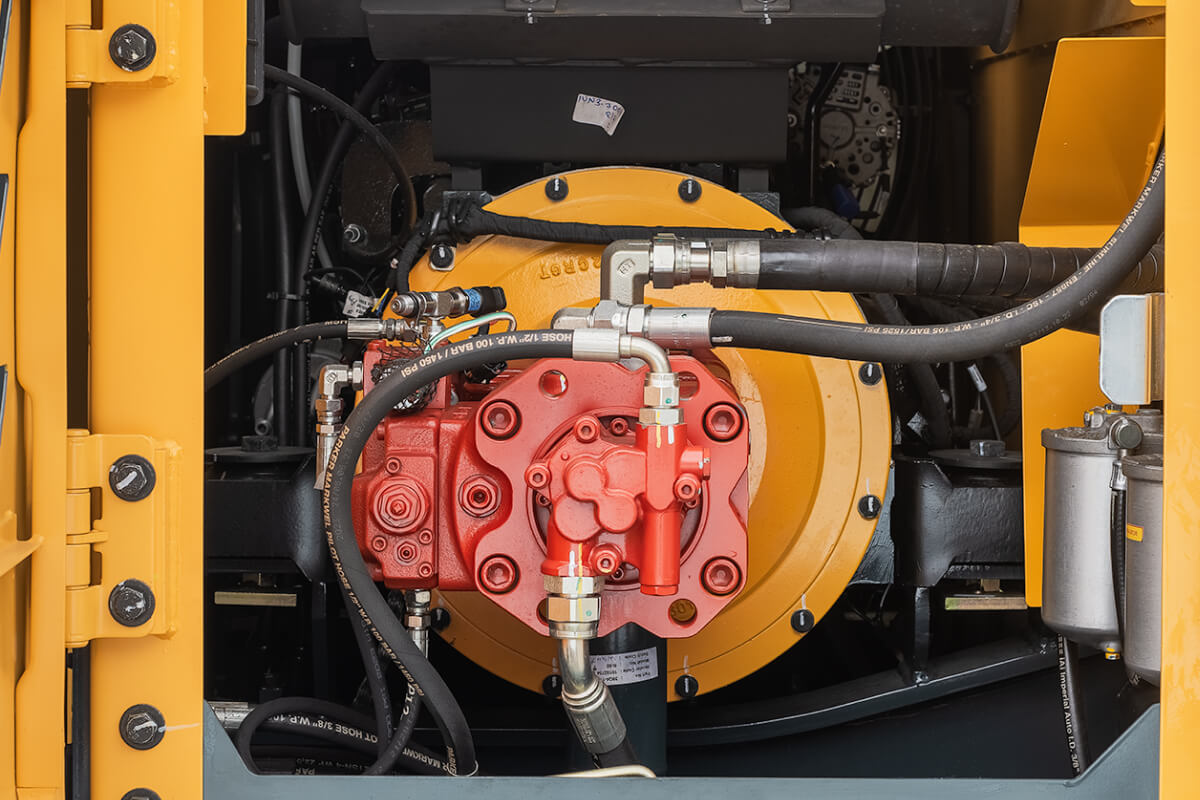

Advance Hydraulics

Regeneration hydraulics feature helps to recirculate hydraulic energy from return line to pump supply line for smooth and fast arm operation. It prevents cavitation and enhances machine performance. The auto-piloted swing priority increases hydraulic oil flow to swing circuit in combined operation, which leads to faster swing cycle for more productivity & profitability.

Power Boost System

This feature helps to meet extreme power requirement when working with peak loads. Operator can activate Power Boost feature, for 8 seconds, to boost digging forces for meeting the work requirement beyond implied limits.